Best Selling Covers

There are two significant maintenance and operation issues that can affect clarifier performance. Algae growth in the clarifier effluent launder channel and odors generated in the clarifier as the effluent breaks over the clarifier weir. Both problems can be dealt with effectively by covering the effluent launder channel with one of several types of Launder Covers.

Simplicity

NEFCO Algae Covers are common-sense designs that have become the best selling covers in North America.

Efficient

The Launder Covers are passive, yet they work around the clock to inhibit algae growth in clarifier launders, saving thousands of man-hours of treatment plant labor every day.

Effective

Algae Covers eliminate algae. They don’t simply brush it into the effluent to create a problem for processes downstream.

Algae Is More Than A Nuisance

Algae growth on launder trough and weir surfaces is a continuous operations and maintenance problem in treatment plants everywhere. At its most benign, algae are an unsightly nuisance that requires frequent cleaning by plant personnel. This is a costly, never-ending process that robs valuable time of maintenance personnel. Unchecked, algae growth can also disrupt weir overflow, clog filter screens and pump mechanisms. In plants equipped with UV disinfection systems, algae in the effluent may significantly reduce the systems’ effectiveness and cause serious maintenance issues.

NEFCO’s patented Launder Cover Systems are designed to inhibit the growth of algae on the launder trough and weir surfaces by blocking sunlight from striking those areas. Without sunlight, algae are largely eliminated, constant cleaning by maintenance personnel is a thing of the past, and the threat of downstream equipment problems caused by floating algae is minimized.

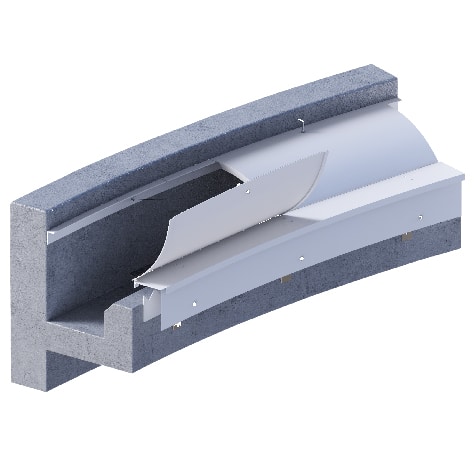

Algae Cover Design

Launder covers for controlling algae generally consist of 1) a fixed mounting section that serves as the base for the Cover, and 2) a hinged cover section that opens to provide access for inspection and maintenance. Together, these two sections extend from the tank wall over the trough and weir to a point just on the inboard side of the scum baffle, completely covering the launder, weir, and scum baffle from sunlight. The large, hinged portion of the cover opens for inspection and maintenance access to the launder trough.

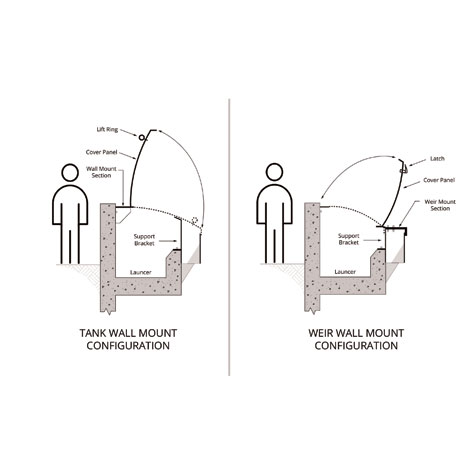

For most plants the Tank Wall Configuration has several drawbacks:

1. The launder cover opens back toward the operator and obstructs his view and access to the trough.

2. Cover installation and alignment are complicated by variations in the “roundness” of the tank wall.

3. The operator must reach over the cover or use a pole or other tool to engage the cover lift ring and open the cover.

Problem Resolution

The Weir Wall Configuration overcomes these problems:

1. The Cover opens away from the operator, providing an unobstructed view of the launder and weir and the operator can access the trough if necessary.

2. The Cover is mounted over the Weir Wall on adjustable stainless-steel brackets, so alignment is independent of tank wall variations.

3. The Cover latch/handle is located immediately in front of the operator. This is a rugged, spring-loaded mechanism that locks the Cover closed but opens easily.

While NEFCO offers both cover configurations, the Weir Wall Mounted Cover is the choice of most plants. The Weir Mount section is secured over the weir wall with stainless-steel brackets. The hinged Cover Section arches over the trough and rests on a cover support flange fastened to the tank wall. Alternate panel units feature a molded tab that seals the panel seams from sunlight.

Launder Covers At A Glance

NEFCO offers cover systems for a variety of clarifier trough configurations, including inboard, outboard, radial, peripheral feed, and others. In addition, NEFCO has developed a number of custom patterns for opening the covers, including alternate, sequential, and unrestricted.

Each Cover panel is manufactured of tough UV-protected fiberglass, specifically designed to withstand the rigors of both the application and the environment. The Cover System is custom engineered to the specific configuration and dimensions of the clarifier for optimum performance and ease of installation. Once installed, unlike “brush” or “sweep” systems, the Cover operates 24/7/365, requires virtually no maintenance and has no parts to wear and be replaced.

NEFCO has been granted a number of US patents for its Launder Cover System designs.