Effective Odor Control System

It is estimated that more than 80% of the odors in the clarifier are produced when effluent breaks over the weir and flows into the launder channel. NEFCO Odor Covers are sealed systems designed to contain these odors and/or operate in conjunction with scrubber systems that draw the trapped gases off and treat them to eliminate the odor. NEFCO Covers are an essential element in an effective odor control system.

In addition, the Cover eliminates algae and acts to keep ice, snow, and debris from the launders, adding to the overall appearance and operation of the facility.

Rugged

Reinforced, walk-on construction offers safe, easy access.

Effective

Sealed units contain odors, eliminate algae, and keep out ice, snow and debris.

Adaptable

NEFCO offers several Odor Cover configurations to suit different needs and applications.

Odor Control Design

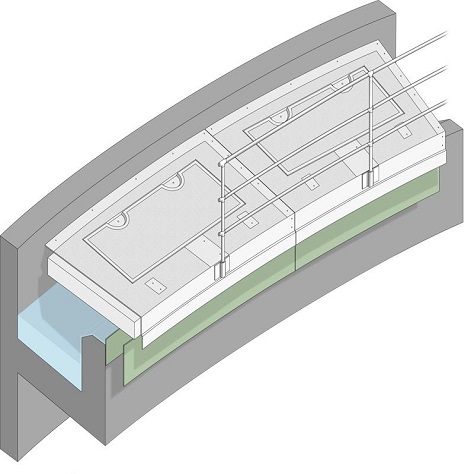

NEFCO’s Odor Control Cover Systems are walkable, load-bearing platforms that enable operators to safely reach covered areas, including launders, grit chambers, UV channels and other areas where personnel access is required. Our walk-on covers feature non-skid surfaces with large hinged hatches that provide ready access to for inspection and maintenance. Heavy-duty construction means that the Cover can accommodate various loading requirements and meet a broad range of local and environmental requirements. Our Cover Systems provide a means of mounting handrails if required.

Typically, the NEFCO Odor Control Cover consists of a series of cover platforms molded to the curvature of the clarifier. The width of the platform extends from the tank wall inward over the launder, weir and scum baffle. The integral scum baffle is designed to extend below the water surface and form an airtight seal. Each cover section normally features two large inspection/access hatches that are hinged to open and sit flush within the cover, eliminating any tripping hazards. The cover platform is fastened to the tank wall and supported on stainless steel brackets at the weir wall. The cover can be equipped with inlet and exhaust connections as well as a safety railing.