Added Efficiency

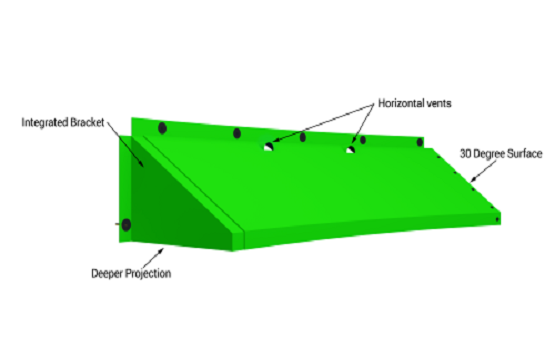

The New Stamford Baffle 3.0 is everything the Stamford Baffle 2.0 is with added efficiency. The new horizontal vents create a jet-like flow that is directed away from the launder/weir wall and won't impede on the surface currents. You'll see a reduction in turbidity at the weir and an increase in baffle performance.

Innovations

Through our continued research and development of the Stamford Baffle design, NEFCO offers the SB3.0. The most efficient Stamford Baffle on the market!

Solutions

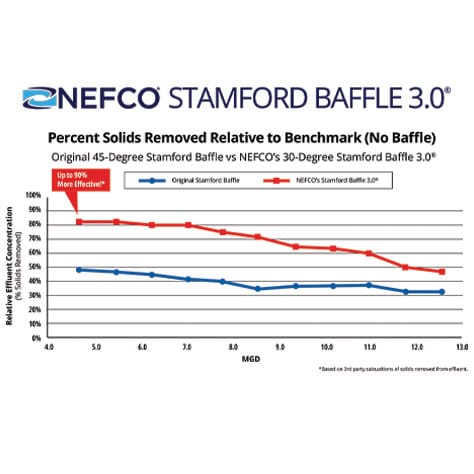

The new SB3.0 offers the unprecedented performance of the SB2.0 design combined with the added efficiency of horizontal vents to provide even better TSS reduction and lower turbidity at the weir for improved clarifier performance.

Revolutionary

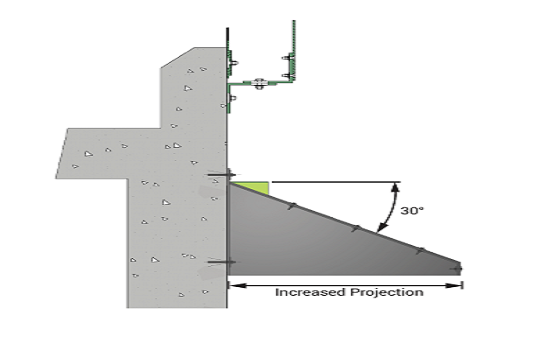

The SB3.0 features the 30-degree inclination angle as measured down from the horizontal and greater horizontal projection from the clarifier wall, calculated as a function of the clarifier diameter.

Density Currents

Density currents form in all activated sludge clarifiers. The dense influent cascades downward and become a current moving in a horizontal plane just above the sludge blanket, attracting lighter solids and short-circuiting the main clarification volume of the tank. The density currents carry the solids to the tank wall and deposit them into the effluent channel, increasing effluent suspended solids and reducing the clarifier’s hydraulic capacity. An EPA consultant, working at the Stamford, CT WWTP in the early 1980’s, conceived of an inclined baffle mounted to the clarifier wall that would intercept these currents and redirect them toward the center of the tank. Several years later, NEFCO implemented that concept by designing and installing the first full-scale, fiberglass Density Current Baffle at the Stamford plant.

Original NEFCO Stamford Baffle

The original NEFCO Stamford Baffle was inclined at 45° and had a relatively small horizontal projection factor. That baffle reduced the clarifier’s total suspended solids (TSS) by roughly 40%. The design quickly became the industry standard. NEFCO’s baffle included two proprietary features: an integrally molded support bracket that simplified installation, and gas vents molded into the mounting flange at the top of the baffle. The 45° baffle continues to be produced by others.

Stamford Baffle 3.0

NEFCO’s Stamford Baffle 2.0 and the new for 2019 Stamford Baffle 3.0, retains all the unique features of the original NEFCO Baffle. The baffle is comprised of individual baffle sections or “modules.” Each module combines the baffle panel, the bracket, the vents and the mounting and stiffening flanges in a one-piece molded fiberglass unit that offers a few advantages:

1. The solid integral bracket at the end of each baffle panel reduces the current velocity below the baffle and contributes to settling.

2. With the integrally molded bracket and other reinforcements, this baffle requires only one bracket per panel.

3. The one-piece, modular design cuts installation time in half.

The Stamford Baffle 3.0 system is readily converted to NEFCO’s new Dual Surface Baffle. This dual surface configuration is designed for larger clarifier operating at very high flows, including combined sewer configurations.

Locating The Baffle

In clarifiers with outboard launders, the baffle mounts to the clarifier wall with the bottom of the baffle positioned mid-way between the top of the sludge blanket and the bottom of the weir. In clarifiers with inboard launders, the baffle will perform most effectively mounted to the tank wall below the launder, so long as there is sufficient vertical clearance to mount the baffle with the bottom of the baffle two feet or more above the top of the blanket. If there is insufficient vertical clearance, the baffle should be mounted to the lower inboard corner of the launder trough. The width of the launder should be included in calculating the horizontal projection of the baffle, but the projection should never be less than 24”.